Projects

We’ve considered well over 1,000 ideas for new medical devices since our establishment. We’ve completed over 210 collaborative workshops and 120 R&D projects.

Our clients come from a range of professions: surgeons wanting to improve the lives of patients; researchers needing assistance to get their research out of the labs and into the hands of end-users; industry from startups to established businesses who are diversifying their product line; and the everyday inventor who sees a problem and has an idea to solve it.

Projects have included special glasses that help frequent flyers and shift workers adjust their sleep cycle, a cancer-detecting probe that is improving surgical outcomes and a device to assist orthopedic surgeons when fixing bone fractures.

A cutting-edge collaboration between North Eastern Community Hospital and the ARIIA x MDPP Ideas Incubator has resulted in several novel prototyped food cutters, enabling kitchen staff to deliver precise IDDSI Soft and Bite-Sized portions (1.5 x 1.5 cm) for residents facing swallowing and chewing challenges.

Through 250 hours of technical expertise from the Medical Device Partnering Program (MDPP) and 30 hours of commercial research via Aged Care Research and Industry Innovation Australia (ARIIA), the project produced three prototypes for North Eastern Community staff to begin trials that can potentially deliver safer, faster, and more consistent food preparation. The prototype cutting tools have potential applications across residential aged care, hospital, disability home care, palliative care, meal delivery services and childcare.

Jack Menzies, founder of Freeline Pty Ltd and an experienced occupational therapist, has developed a lifechanging innovation—the Mobile Step-Climbing Shower Commode—which has the potential to assist older Australians safely overcome bathroom steps and thresholds.

The solution was created through a close collaboration with Aged Care Research and Industry Innovation Australia (ARIIA) and Flinders University’s Medical Device Partnering Program (MDPP) as part of the now concluded ARIIA x MDPP Ideas Incubator.

Automatic Smart Pressure Cushion

For people with reduced mobility who spend extended periods seated, pressure injuries aren’t just uncomfortable - they can be painful, life‑altering, and even life‑threatening.

Adelaide innovator Mossa Medical is tackling this challenge through the ARIIA x MDPP Ideas Incubator, coordinated by Aged Care Research & Industry Innovation Australia (ARIIA), with technical support from Flinders University’s Medical Device Partnering Program (MDPP).

Reminu

A revolutionary digital platform is set to transform aged care by enabling organisations to deliver truly client-centred care - improving resident wellbeing and providing peace of mind for families across Australia.

Founded by New Word Order, Reminu was developed through a strong partnership with Aged Care Research & Industry Innovation Australia (ARIIA) and Flinders University’s Medical Device Partnering Program (MDPP) via the ARIIA x MDPP Ideas Incubator.

The platform provides user-friendly software accessible on handheld devices and desktops to document life stories, preferences, and future care plans. It gathers information directly from individuals and trusted sources, ensuring wishes are shared with care providers while preserving a dignified legacy of their life.

DeflectaCath tipped to redefine urological care.

An Australian clinical surgeon has collaborated with the Medical Device Partnering Program (MDPP) at Flinders University to develop a novel catheter for safely navigating the intricate curves and contours of the male urinary tract.

Urological surgeon Associate Professor Ian Middleton developed "DeflectaCath," a silicone catheter equipped with a unique deflection mechanism in its tip, to simplify the insertion procedure for clinicians and improve the health outcomes for patients.

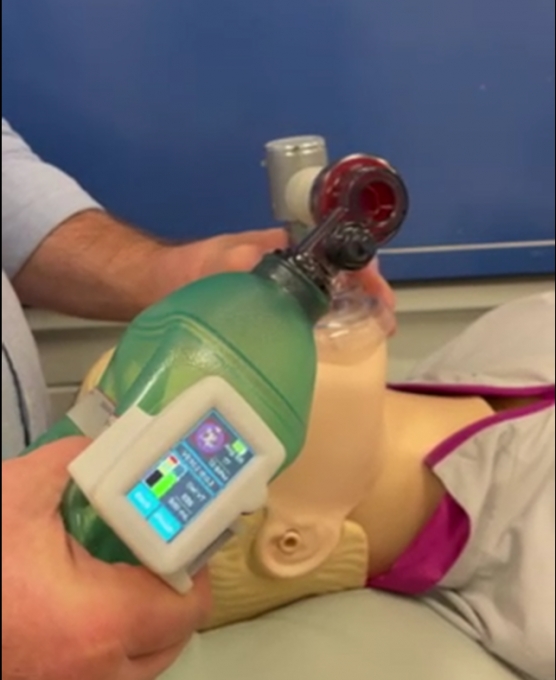

Ventilation management during life-saving resuscitation is being transformed by a local start-up, Abtulus®, who have partnered with the Medical Device Partnering Program (MDPP) at Flinders University to develop a novel Bag Valve Mask (BVM) guidance system.

Engineered by Dr Siavash Noor (Ahmadi Noorbakhsh) of Abtulus®, VentiWatch is a practical, simple and reusable ventilation management solution supporting medical professionals and first responders with the delivery of precise and efficient ventilation during resuscitation.

Revolutionising the landscape of healthcare delivery, innovator Hayley Saddington has joined forces with Flinders University's Medical Device Partnering Program (MDPP) to build a cost-effective, clinically guided digital software application tailored for supporting in-home rehabilitation.

The co-founder of Peak Medical, Hayley is a visionary in her field who has exploited artificial intelligence to create an innovative technology which empowers in-home patients to progress their rehabilitation with the confidence of precise clinical guidance.

create an innovative technology which empowers in-home patients to progress their rehabilitation with the confidence of precise clinical guidance.

Replicating the physiotherapy experience, the technology employs an evidence-based clinical approach, directing individuals to customised exercises for continuous improvement between appointments.

Each year, approximately 1.7 million pacemakers are implanted worldwide, with over 30,000 of those in Australia, significantly improving recipients’ health and life expectancy.

A South Australian company, C.tech (Cardiovascular Technology Services Pty Ltd), based at Flinders University, is revolutionizing pacemaker surgeries. The company’s OnePoint Junction Box helps take the guesswork out of surgery, ensuring better outcomes and even extending the pacemaker's lifespan. This device is now sold in 26 countries, contributing to a sales surge, reaching $1 million.

Founded and led by Darius Chapman, C.tech is a bootstrapped medical device company that works with multinational companies and serves an international market. The company’s team is small but dedicated to solving critical problems in cardiac care, especially for patients with electrical heart abnormalities.

Who are you?

Our company has been working on the development of a smart mechanical device to assist with rehabilitation following shoulder surgery. The device was created to allow passive shoulder ROM in the home or clinical setting, by driving the arm along a surface to allow safe mobilisation in the early stages of rehabilitation.

We aim to deliver an advanced solution to improve clinical outcomes following shoulder surgery, with a focus on patient experience, data collection and enhancing the connection between patient and practitioner. We aim to do this using the physical device, which links to a smart application and feeds data back to the practitioner. Our engagement with the Medical Device Partnering Program has been crucial in guiding and supporting us as young practitioners with an idea, through the process of developing that idea into a physical product and looking towards commercialisation of that product.

Designed by a Dental Hygienist to be the ultimate mouldable mouthguard. NeoMorph is a hybrid, combining the best qualities of the professionally made mouthguard with the convenience of a “boil & bite”. No more bulky, ill-fitting guards that dislodge on impact or bond to orthodontic appliances. NeoMorph is a pioneering over-the-counter sports mouthguard delivering a level of protection and custom fit previously unexpected in a reformable mouth guard.

Approximately 76,000 pregnant women and 500,000 babies die from pre-eclampsia across the world every year. Women in developing countries are seven times more likely to suffer from the condition due to delayed diagnosis and a lack of access to hospitals.

Causes of pre-eclampsia are not entirely understood, but if left untreated it can lead to blood clots, organ failure, and death. Rapid, affordable, and accurate diagnostic tools are therefore essential in aiding treatment.

Now, with the help of the Medical Device Partnering Program, a portable diagnostic device being developed by Professor Benjamin Thierry, Dr Duy Tran and a team from the University of South Australia’s Future Industries Institute (UniSA FII) has shown it could pose a solution.

What started as a family injury has turned into a rehabilitation game-changer receiving global attention.

The Prohab Connected Healthcare Device, the brainchild of physiotherapist Lyndon Huf, is an innovative rehabilitation device that accurately measures the force-generating capability of an individual’s muscle, in order to guide and personalise prescription of exercise and rehabilitation programs .

Page 1 of 2